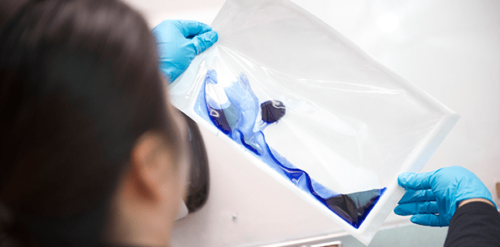

Before you set out to validate a medical device package design or process, you’ve got to do your homework in order to understand what is critical to build the proper foundation for a sterile barrier system and to avoid a breach of that system. Scott Levy, senior packaging engineer for DDL, offers the following 10 points to consider before beginning any packaging validation effort.

Before you set out to validate a medical device package design or process, you’ve got to do your homework in order to understand what is critical to build the proper foundation for a sterile barrier system and to avoid a breach of that system. Scott Levy, senior packaging engineer for DDL, offers the following 10 points to consider before beginning any packaging validation effort.

- Understand the regulatory requirements (FDA, EU, etc.). In general, regulators expect you to prove that your packaging system ensures sterility maintenance of that device and to confirm the consistency of your processes.

- Read and familiarize yourself with ISO 11607 so you understand your validation responsibilities. To obtain a CE mark for marketing your medical device in the EU, you must be in compliance with ISO 11607. The good news is that ISO 11607 is also recognized by the U.S. FDA as a consensus standard, so if you are in conformance with it, you will have a much easier time complying with the FDA.

- Get your package professionals involved upfront in the product design process. Packaging professionals should be working with colleagues in regulatory, product development, and quality as early as possible during medical device development.

- Perform a risk assessment of the medical device you are packaging. Determine the specified attribute data for your package, identify all potential failure modes that could cause (or result from) an out-of-specification package, and then determine the sample size needed to catch those failures.

- Talk to your suppliers and service providers. Your vendors have a lot of knowledge about materials and processes, especially when it comes to materials for packages such as pouches and trays. Get as much data as possible from material providers, thermoformers, and package converters, and don’t forget to work closely with machinery providers, who in addition to providing process validation support might also consult on material performance.

- Write your packaging protocol and establish clear acceptance criteria. Make sure your protocol includes the following: a purpose, a scope, a reference section listing all standards and test procedures, descriptions of all materials and equipment, all attribute data, a sequence of events or a flow chart of what will transpire, and a summary of the chosen sample size and acceptance criteria. It is important to document everything.

- Know your worst cases. Review your product families to define all worst-case scenarios for what potentially can cause the most adverse effects to the package. When identifying a worst case, look for the heaviest, the lightest, the largest, and the smallest. It is a hard question to answer, but you are looking for what potentially can cause the most adverse effects to the package.

- Understand the differences between package seal strength and whole package integrity as well as stability testing and package performance. Many people start using test methods before they understand the standards. Before you start any test you need to understand what you are testing, look for test methods that have been validated, and then validate that you can perform them according to the standardized methods.

- Do a gap analysis of the test standards that you have previously utilized to what is current. Do a gap analysis when any new standards are released or if there is a change in packaging materials or processes.

- Make sound technical science-based justifications if needed. If making a justification, you need to take a look at all factors for a particular justification and make it science based and defendable.

By doing their homework with materials and processes and by understanding what they need to do before validation, medical device packaging professionals will build a successful validation program.

For more details, please download a copy of DDL’s SmartGuide.

One way to explain the use of the Arrhenius equation and Accelerated Aging Factor (AAF) Determination to someone outside of the profession is to describe it as a time machine. The use of these equations allows the engineer to essentially make time go faster in order to prove out their packaging that much sooner.

One way to explain the use of the Arrhenius equation and Accelerated Aging Factor (AAF) Determination to someone outside of the profession is to describe it as a time machine. The use of these equations allows the engineer to essentially make time go faster in order to prove out their packaging that much sooner. ASTM D4169-09 recently has been revised to ASTM D4169-14. ASTM D169 is the test method performed by subjecting shipping units to a test plan consisting of a sequence of hazard elements which would be encountered in various distribution environments.

ASTM D4169-09 recently has been revised to ASTM D4169-14. ASTM D169 is the test method performed by subjecting shipping units to a test plan consisting of a sequence of hazard elements which would be encountered in various distribution environments.