In this edition of DDL’s PackReview series, DDL Packaging Engineers Scott Levy and Peter Johnson discuss the following topics on ASTM –F1929 Dye Penetration testing:

- What is Dye Penetration?

- Why use it?

- What are the different methods?

- What are the major concerns?

- Can anybody do ASTM-F1929?

Dye Penetration is a physical seal integrity test. The test is meant for seals constructed of one clear material side and the other side consisting of wicking material such as Tyvek material or paper. The dye penetration test is a great seal integrity test with a high degree of sensitivity. This test is primarily used in sealer process qualifications.

Why use Dye Penetration? Dye Penetration is a quick and efficient way to make sure that you have a quality seal. This is a perfect test for sealer process qualifications.

Why use Dye Penetration? Dye Penetration is a quick and efficient way to make sure that you have a quality seal. This is a perfect test for sealer process qualifications.

There are three different Dye Penetration methodologies.

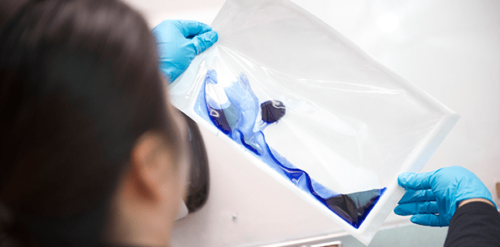

- Method A: with this method you inject the dye solution within the package and observe the seal for any channel or leaks.

- Method B: is the Edge Dip method. This is where you will take the package and physically dip the edge into the dye solution then watch for any wicking upward for any channels. The key to this method is to make sure the edge of your seal is at the edge of the package. If there is any excess material you need to remove that material before you proceed with the Method B edge dip.

- Method C is the Eye Dropper method. This method can be used on packages with excess material which extends beyond the seal. Per this method you want to separate the two materials and put a bead of the dye solution along the outside edge and look for channels.

Method A is the one that is most commonly used of these three procedures. The other methods can be considered based on the scope of the project.

One of the potential pitfalls when using the dye solution is you can get false positives. The procedure specifies you should only leave the dye solution in for twenty seconds, which would be five seconds on each side. If over exposed the dye solution can bleed through the wicking material, which can cause a false positive. Another potential false positive can occur when there is de-lamination, as the dye solution often finds the separation between the two materials, which can appear as a failure in some instances.

In order to do ASTM-F1929 Dye Penetration testing there are two things that need to happen. First you need to have your test method validated, and second you need to make sure that you use the formula as specified in the standard. When using Dye Penetration you will need to make sure you can identify the channels and insure there is no variability between your procedure and who is doing the test.

Thank you for watching DDL Inc PackReview series on ASTM- F1929 Dye Penetration. If you have any questions please contact us to speak with one of our packaging engineers.

ISO/IEC 17025:2005 is the international standard by which a laboratory’s commitment to quality and technical competence are evaluated. DDL previously achieved ISO/IEC 17025:2005 accreditation for its distribution testing, and strength and integrity testing by demonstrating its laboratories are in compliance with the standard and A2LA accreditation requirements.

ISO/IEC 17025:2005 is the international standard by which a laboratory’s commitment to quality and technical competence are evaluated. DDL previously achieved ISO/IEC 17025:2005 accreditation for its distribution testing, and strength and integrity testing by demonstrating its laboratories are in compliance with the standard and A2LA accreditation requirements. When choosing a technique the key word is consistency. When you are looking to do ASTM F88 Seal Strength testing, choose a technique and stay with it throughout the project so you can get consistent results. If you do decide to change techniques in the middle of a project your data will change as well.

When choosing a technique the key word is consistency. When you are looking to do ASTM F88 Seal Strength testing, choose a technique and stay with it throughout the project so you can get consistent results. If you do decide to change techniques in the middle of a project your data will change as well. DDL, Inc. is celebrating its 25th anniversary of providing package, product and material testing to the medical device industry.

DDL, Inc. is celebrating its 25th anniversary of providing package, product and material testing to the medical device industry.